Cotton Skirts

Organic Cotton Fields

We purchase our organic cotton directly from over 2000 cooperative farmers in Nicaragua, making $400 prepayments each June for every 1000 lbs. of organic cotton we need for the following year. Our investments cover approximately half of the farmers’ annual cultivation costs. In December when the crop is harvested, Maggie’s pays the entire balance, at prices often higher than the established fair trade price. In this way we share our farmers’ risks, and we guarantee our customers a steady supply of great quality organic cotton. We have worked with these growers for many years through our NGO Jubilee House Community, helping to develop a special variety of cottonseed which is revitalizing both soils and an industry. Sharing risks and staying the course with cooperative farmers is what we call real fair trade.

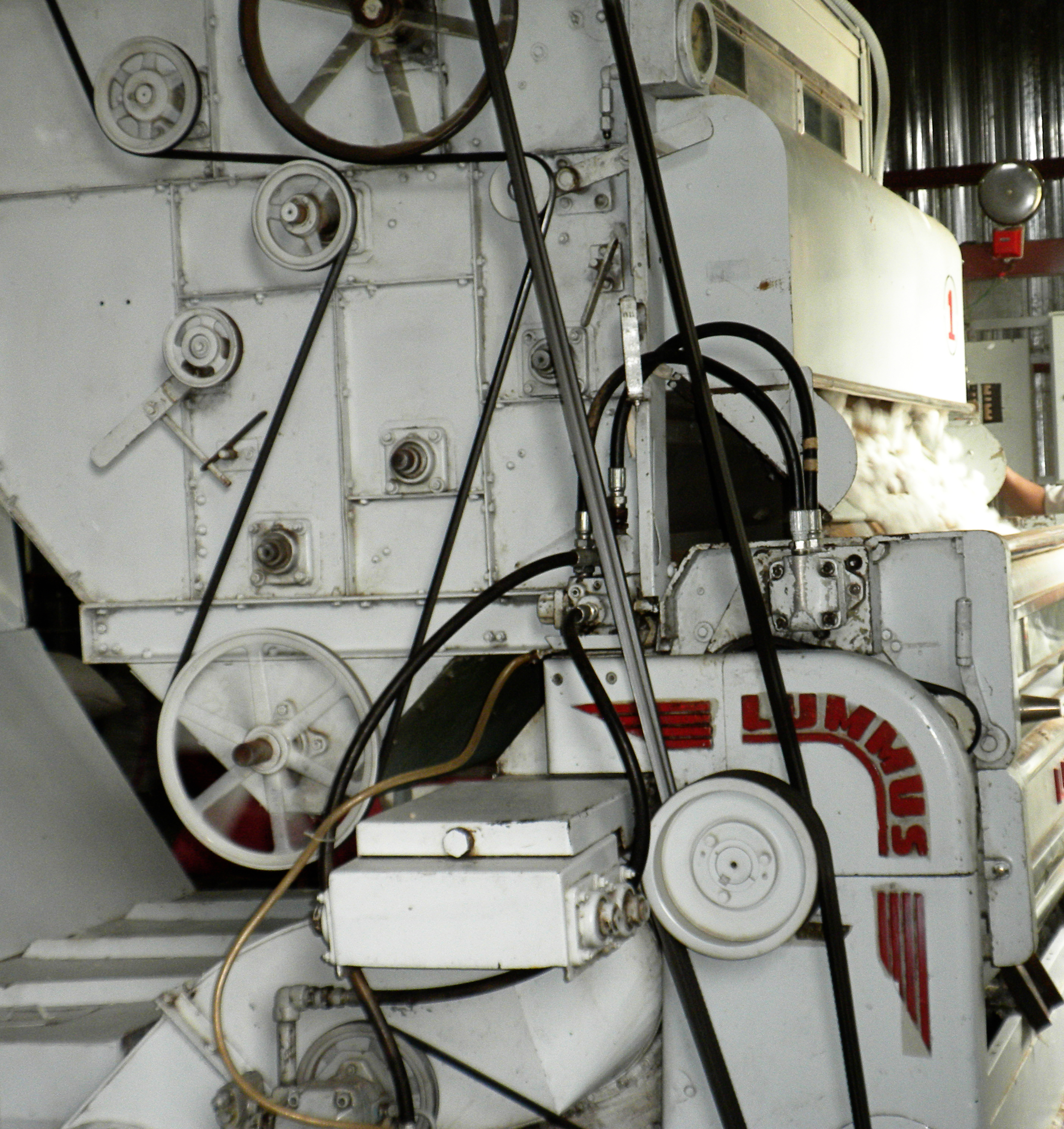

The Gin

All of the cotton used in all of Maggie’s socks is ginned at a 100% worker-owned cooperative that is run by the farmer co-ops. Once the truckloads of seed cotton arrive at the gin, worker-owners run the equipment and bale the ginned cotton in preparation for shipment to the spinner. Maggie’s has stayed with this project through the early years of trials, even helping to hand-clean the fiber when needed. We pay for all ginned fiber as soon as it is completed, enabling the farmers to reap the harvest of their labor. Establishing long term relationships with our producers and making financial investments in their work is what we call real fair trade.

Spinning

Our spinner is a family-owned-and-operated mill located in San Salvador. As one of the largest mills in Central America, organic cotton is a small part of their business, but they have provided both technical and financial support to our cooperative farmers, and they respect the direct relationship we have with these growers. They work with us to make sure the blend of our fiber and the twist in our yarn is adjusted each year to assure the highest quality socks, and they do it all in accordance with GOTS (Global Organic Textile Standards). Communication with and respect for our vendors is what we call real fair trade.

Knitting

Our organic cotton yarn spinner provides knitting, and once we learned that they could handle low-impact fabric printing, we worked for several months on our first-ever print colors, the stripe series for our Hairware and later our Bias cut Skirts. Increasing capacity and diversity through ourcurrent partners, and developing new products around the abilities, is what we call real fair trade.

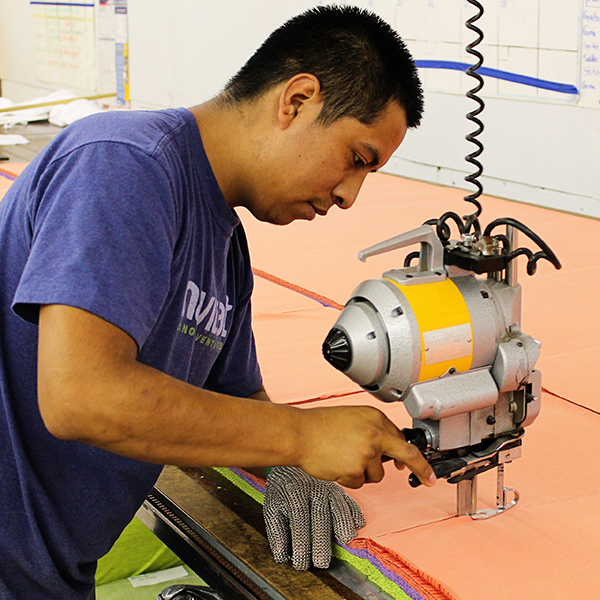

Cut & Sew Cooperative

Ever since we set up a successful worker-owned sewing cooperative in Nicaragua, we imagined bringing the idea home to the U.S. In 2008, we found the partners we needed to do just that in a small mill- shuttered town down the mountain from Asheville, North Carolina. Beginning with a project making whimsical stuffed animals from our excess socks, we sponsored and developed Opportunity Threads from the ground up. They are now a growing and diverse sewing facility that currently makes all of our Hairware and Skirts. Worker independence and engagement is what this project is all about, and OT is living proof of the quality the flows from respect and dignity.

More Behind The Label: Cotton Socks | Wool Socks | Leggings | GOTS Sweater Knits | Made in USA Skirts | GOTS Apparel