Wool Socks

Organically Raised Sheep

Our Organic Merino Wool is grown by over 100 family farmers in the Chubut region of southern Argentina, known for its clear Chubut River, many wildlife species, and eternal winds. Maggie’s sheep farms are each several thousand acres, as much of the land is arid, with an average of 1 sheep grazing for every 3 acres. Our sheep are raised to the same standard as sheep raised for organic dairy and meat and are regulated by the US Organic Rule. Taking the time and effort to understand the overall financial status of our farmers is what we call real fair trade.

Fiber Processing

Processing wool into finished socks is a long-detailed process. We source our Organic Merino Wool tops through a special top-maker in Germany. Tops are the sheared wool from sheep after it has been washed and combed. Our organic wool is specially treated with one of only two certified eco-friendly washable wool treatments certified by GOTS (Global Organic Textile Standard). Natural wool contains small scales that need to be removed before the wool can hold up to machine washing and drying. Commercial wool is made washable by adding chlorine and chemical polymers. Our organic wool endures a much more gentle anti-felt process that take longer, but is chlorine-free. Batch after batch of high quality, thick and soft Maggie’s Hikers, Snuggles and comfy Wool Crews all wash and dry great. Just wash your wool socks inside out, and they will stay soft and stretchy for years. Working with suppliers to constantly improve quality without raising prices is what we call real fair trade.

Spinning & Dyeing

Maggie’s Organic Wool Tops are spun into our organic yarn for our wool socks at a 50-year old spinning plant in Poland. The process to make the wool tops into yarn involves opening the bales, carding the fiber (creating a thin web) to form a rope-like strand called a sliver, combing to remove short fibers and impurities, drawing the sliver out into a thinner strand, and finally spinning into the organic wool yarn.

After the yarn is spun, it is sent for dyeing at our GOTS-certified dye plant in the beautiful village of Simleu Silvanie Romania. This plant became part of our wool supply chain in 2010, employing 350 people out of the village’s 14,000 inhabitants.

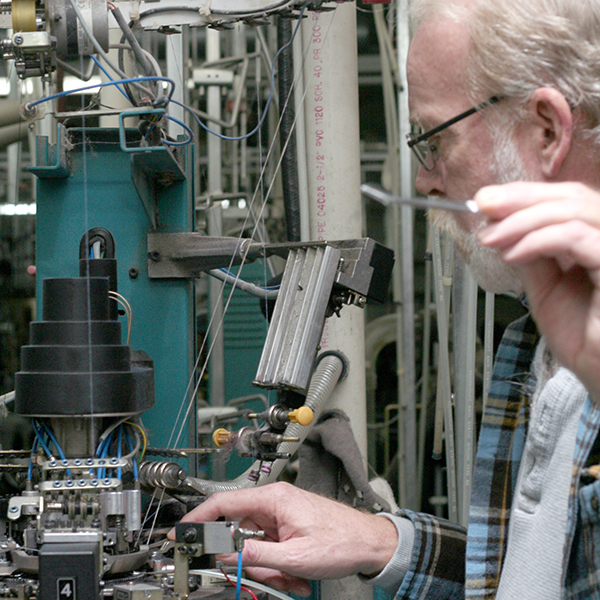

Knitting

From the spinning and dyeing in eastern Europe, Maggie’s ships our wool to three different generations-old family knitters located in North Carolina, USA. Together, these knitters are living proof of the tenacity and perseverance of the American spirit.

One knitter outside of Raleigh works the mill that's been in their family for three (going on four) generations, and still provides health care to their employees.

Our knitter south of Winston-Salem is a third-generation techie bringing new seamless toe machines to his grandpa's business.

Just like all of our organic cotton, at Maggie’s we process and purchase all of our organic wool yarn. That's unusual in the apparel industry. As a result, our US knitters can produce our socks without having to purchase their main raw material. With each purchase order, our knitters use the yarn we at Maggie's own, and bill us as if it's theirs. We deduct the cost of the yarn, but we pay them as a full-package vendor. Our system helps their cash flow and assures us both that our organic yarn is tracked through every step of production. Our financial advisors think we're crazy, acting like a bank to our vendors. But we see it differently. We could move all of our sock production offshore, and save 30+% of our costs. But the Maggie’s way is to partner with our suppliers, and to continually improve our quality and our sale. This helps us secure good quality organic wool. And we help grow manufacturing jobs in the US. A win-win-win-win situation.